2nd Hand Equipment - Coming soon!

We are now putting the final touches to the World Mining Equipment 2nd Hand market place. If you would like information on this service contact

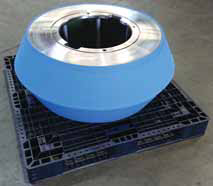

Glencore Technology reported it commercialized conical spacers for their Isa- Mill fine grinding technology. Tests in an M1000 IsaMill, processing pyrite concentrate for gold recovery, showed they reduced the specific energy requirement by 12.7% to 21.5% depending on the P80 requirements, the company reported. The greater the fine duty, the greater the savings recorded.

The conical spacers are best suited to sites with relatively fi ne grind-size targets and high specific energy consumptions, Glencore Technology reported. They have no adverse effect on the particle-size distribution.

Leadership at Glencore Technology reported the spacers offer the potential to significantly reduce operating costs. “These savings make it incredibly compelling to retrofit existing IsaMills, and to specify an IsaMill in any redesigned or new flowsheet,” said Virginia Lawson, technology manager, Glencore Technology.

The first IsaMills, which are still in operation, were deployed approximately 25 years ago to McArthur River zinc mine, in the northeastern Northern Territory, Australia, and the Mount Isa zinc mine in Queensland, Australia.

http://www.glencoretechnology.com